Chemical vapor infiltration method of ceramic matrix composites fabrication is a process in which reactant gases diffuse into an isothermal porous preform made of long continuous fibers and form a deposition.

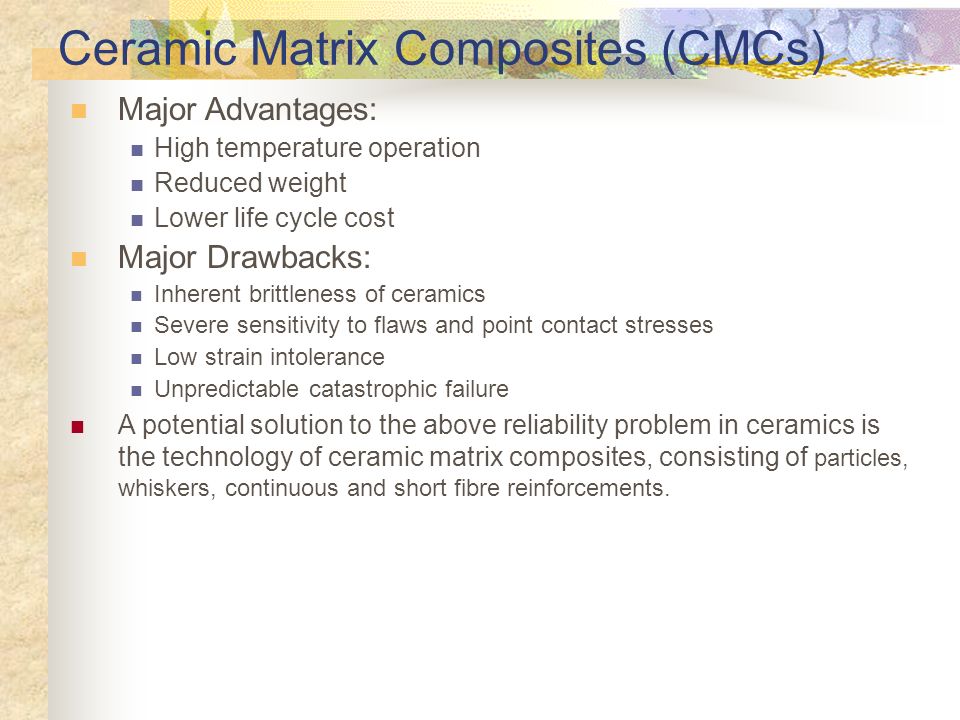

Disadvantages of ceramic matrix composites.

Application and properties of ceramic matrix composite.

Cmc materials combine the best advantages of the engineering ceramics and fibre reinforced composites.

The infiltration of the gaseous precursor into the reinforcing ceramic continuous fiber structure.

001511303001 jadavpur university kolkata.

High hardness and strength excellent wear and corrosion resistance moreover they feature significantly improved fracture.

Cmcs are designed to overcome the main drawback of monolithic ceramics namely their brittleness.

Cmc is a new class of ceramic based materials that contain ceramic matrix reinforced by carbon or ceramic fiber.

As manufacturers have also found ceramics have challenges in machining and in cost.

Advanced ceramics ceramic matrix composites.

Both the matrix and the fibers can consist of any ceramic material whereby carbon and carbon fibers can also be considered a ceramic material.

Ceramics matrix composite 1.

Ceramic matrix composites cmcs are a subgroup of composite materials as well as a subgroup of ceramics they consist of ceramic fibers embedded in a ceramic matrix.

Ceramic matrix composites cmcs generally consist of ceramic fibers or whiskers in a ceramic matrix.